Key typical process solution

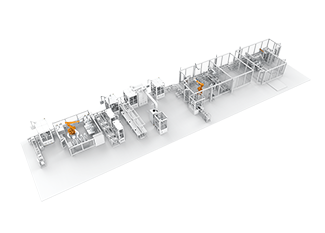

Turnkey Solution of New Energy Electric Drive System

A turnkey solution including sub assembly and assembly of motor, reducer and controller, and inline product test and offline test. A "butterfly" layout can be applied to integrate the sub assembly line of rotor, stator and reducer, etc., and AGV sytem can

Automatic technology

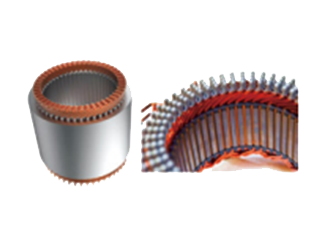

Automatic Hair Pin Stator Manufacturing Solution

Capable of laser striping, 3D bending, terminal reverse folding, clip grouping & insertion, separate servo for twist molds, laser/TIG welding and automatic transfer between stations of coating, trickling and testing.

Self-developed core software

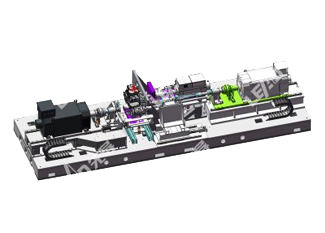

Automatic Electric Drive Offline Testing System

Capable of auto lubrication, auto cooling, auto test pipe connection, auto testing clamp, integrated software write-in system, testing process monitoring, and integrated peripheral function devices

Magnets processing speed of 4s/pcs/pt

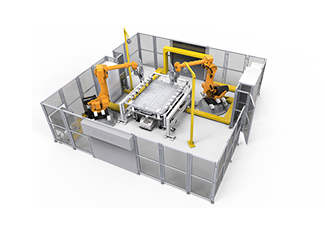

Stator Line -- Magnets Insertion Machine

The rotor manufaturing solution based on robot transfer offers the greatest flexibility to the process. The magnets insertion and dispensing equipment owning an independent intellectual property realizes magnets processing speed over 4s/pcs/pt, and is com

Custom configuration, Flexiblility test, Easy to operate and maintain

Electric Drive Universal Automation Test Software

It has functions of automation test, test result query, DSO, data analysis, inline report, remote access, smart diagnosis, modular customization and tool library, etc.

Support various types of products, Customization

Data Management System of Digital Plant

Configured with process optimization, quality assessment, trend prediction, intelligent operation and service, smart diagnosis, real-time monitoring and mobile working, etc.