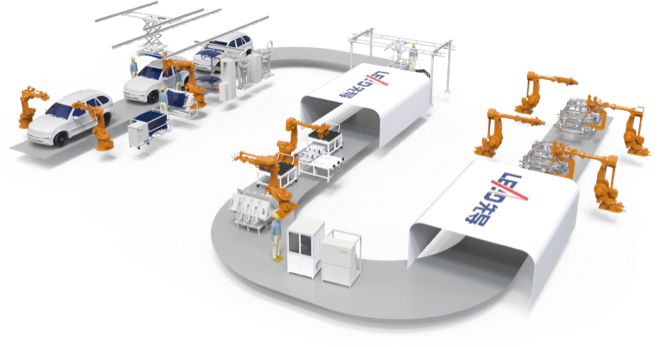

3C INTELLIGENT EQUIPMENGT

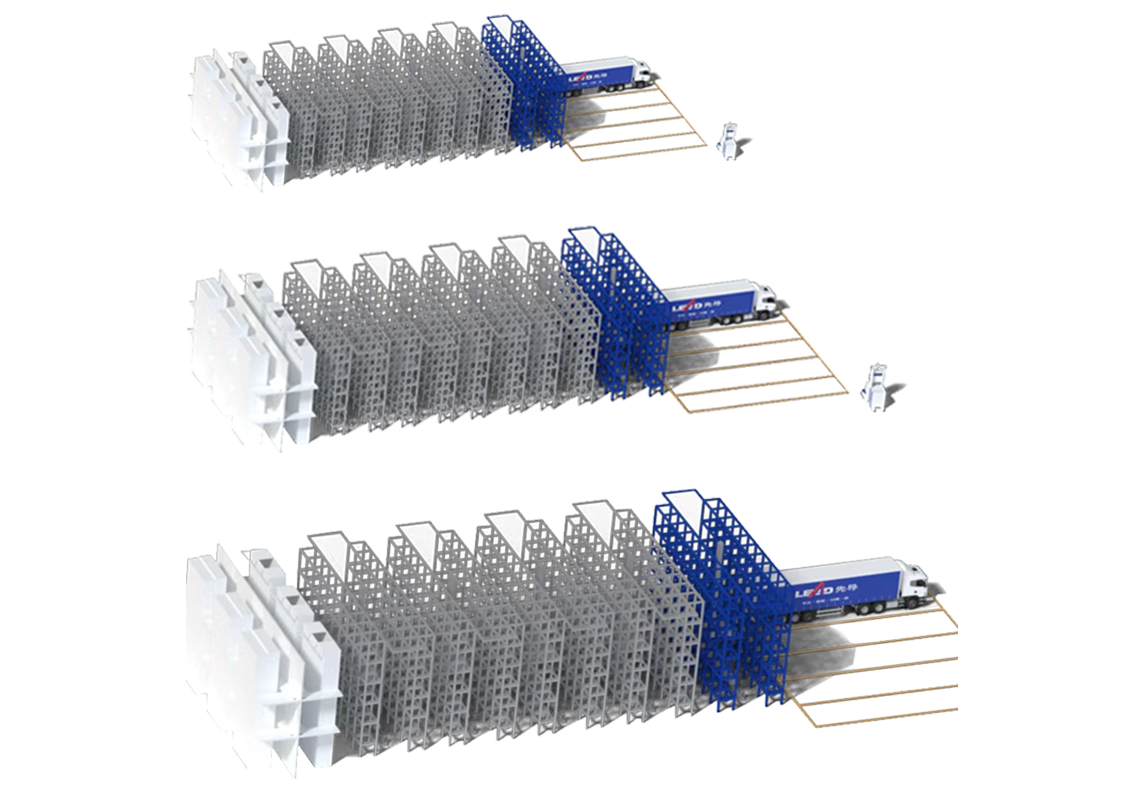

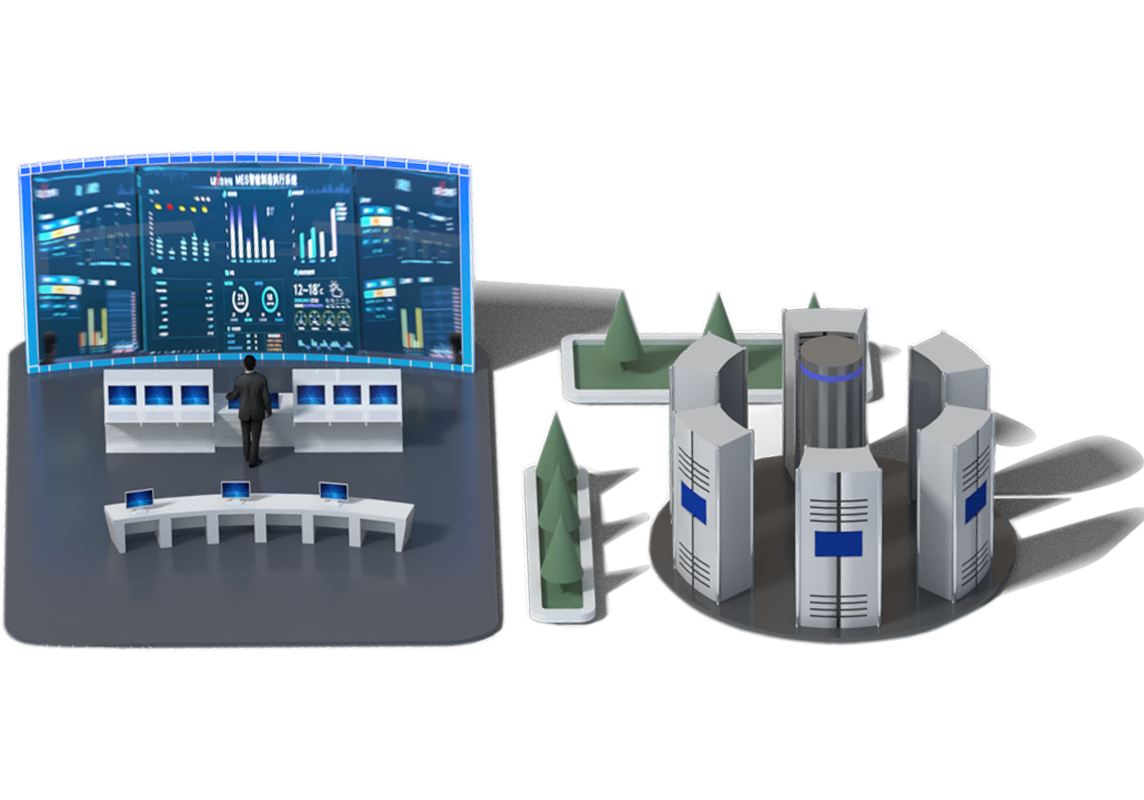

As the world's leading intelligent manufacturing turnkey solution provider, Its products cover 8 series, including Vision Metrology, Precision Fluid, Camera Test, AI Inspection, Advanced Surface Treatment, 3D Bonding, Reliability Test and Integrated Assembly, focuses on the global consumer electronics, automobile & energy, pan-semiconductor, precision sensor and other intelligent fields.

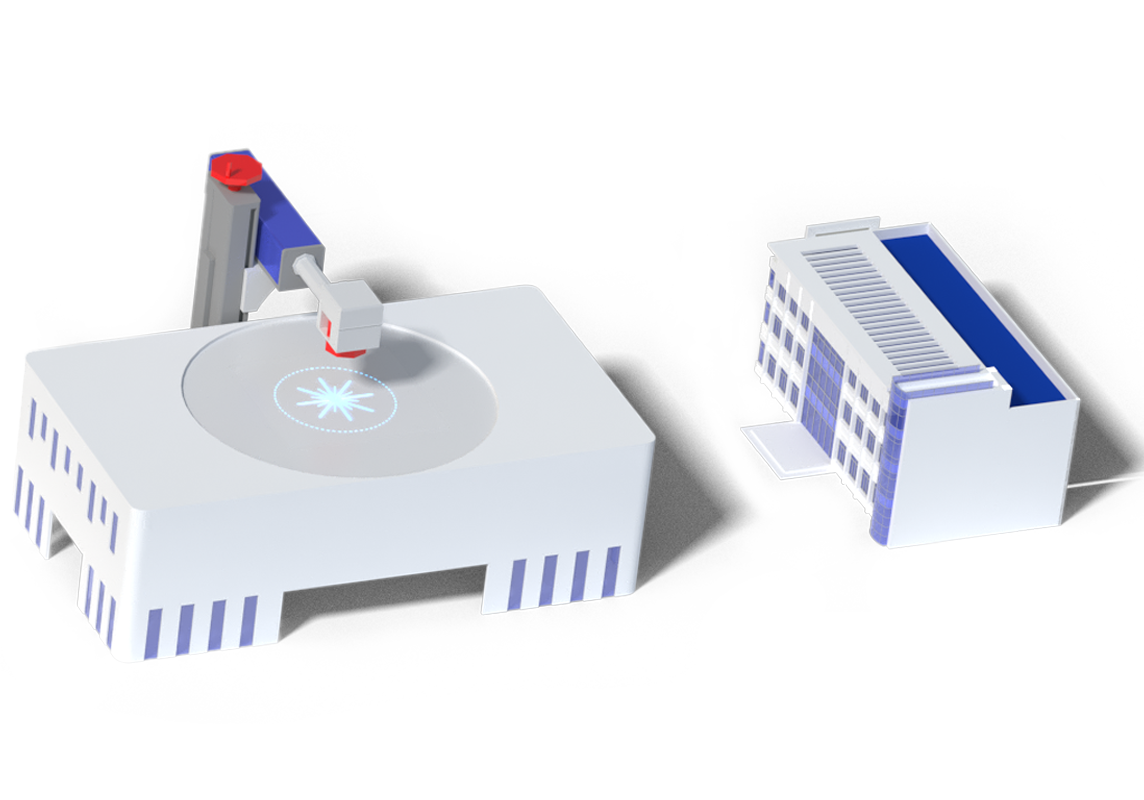

LEADTECH provides competitive products and services to satisfy the diverse demands from customers by integrating technologies (solution of real-time 3D stereo vision, micron-level motion control, sub-pixel image processing, artificial intelligence) and self-developed software and algorithm platform (3D algorithm platform, AI inspection platform,Advanced fluid technology and μm level multi-axis control system) , and become the strategic partner for top customers in industry.

Self-developed Core Technologies

3D Algorithms Platform ,AI Inspection Platform、μm Level Multi-axis Control System

Product

Lines

Vision Metrology 、Precision Fluid、Camera Test、AI Inspection、Advanced Surface Treatment、3D Bonding、Reliability Test、Integrated Line